Civil Engines

C.E. Civil Engines Ltd was established in 2016 as an engineering company in the Republic of Cyprus, Limassol.

The oil and gas industry, in the long run, takes a key role in the scale of the entire economy of any country, and therefore, C.E. Civil Engines Ltd, as a part of its strategy, aims to further expand its presence in this industry as a stable supplier of equipment, services and solutions to any task.

Based on the knowledge and extensive practical experience of the Civil Engines specialists, the services that are offered by the company are – the choice of economically viable, integrated solutions for implementation of complex and specific tasks, such as:

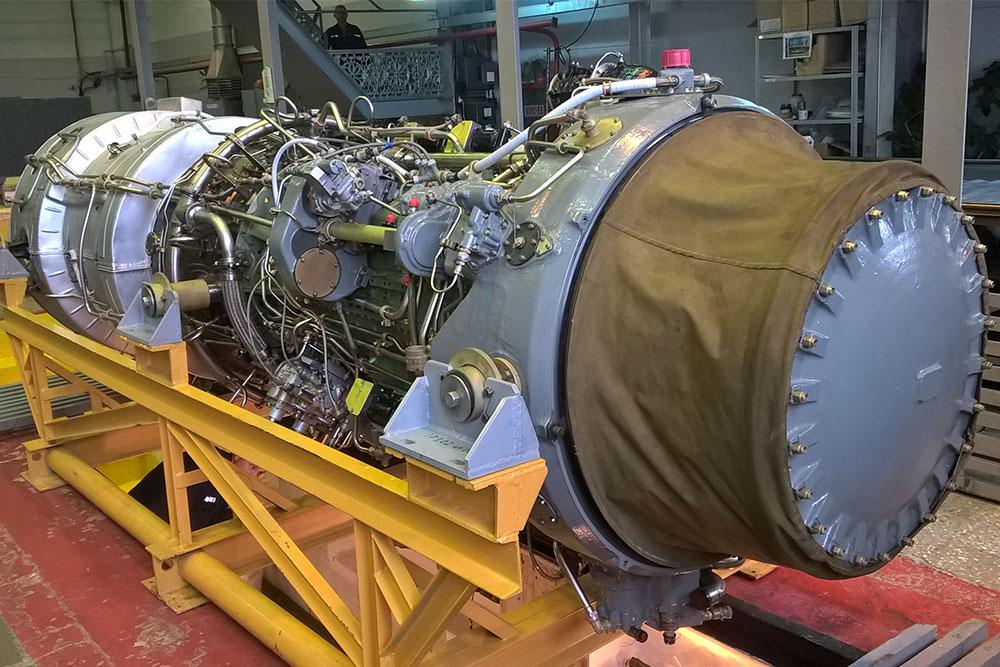

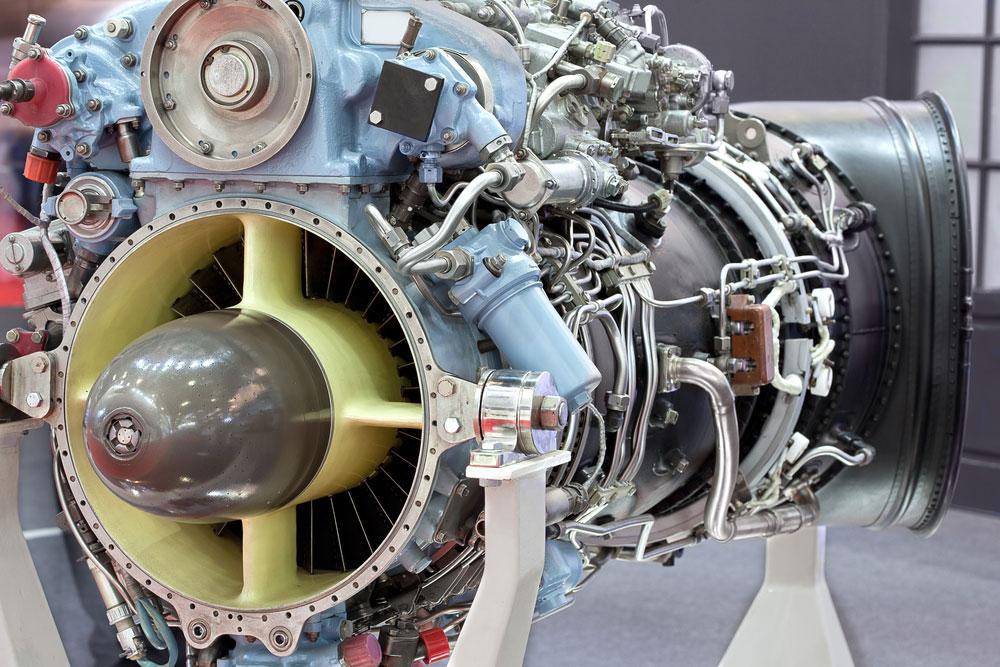

• supply of new gas turbine engines and power turbines;

• overhaul of gas turbine engines and power turbines;

• supply of spare parts for gas pumping units;

• installation and commissioning of equipment for gas pumping units;

• technical diagnostics and analysis of the technical state of gas pumping units.

C.E. Civil Engines Ltd in cooperation with its partners, implements overhauls and emergency repairs of gas turbine engines - drives of gas compressor units (GCU) such as NK-12ST, NK-14ST, NK-16STD, NK-16-18STD, AI-336-2-8, D-336-2, DG90L2, DU80L1, gas generators LM-1600GE, LM-2500GE, modules of power turbines EGTK0140 GCU DATUM and DR-61 GCU DATUM.

C.E. Civil Engines Ltd in cooperation with its partners, implements overhauls and emergency repairs of gas turbine engines - drives of gas compressor units (GCU) such as NK-12ST, NK-14ST, NK-16STD, NK-16-18STD, AI-336-2-8, D-336-2, DG90L2, DU80L1, gas generators LM-1600GE, LM-2500GE, modules of power turbines EGTK0140 GCU DATUM and DR-61 GCU DATUM.

In 2017, C.E. Civil Engines Ltd established a foreign company Engine-Service LLC on the basis of Bukhara Repair-Mechanical Plant JSC and created the Maintenance Center on its base. It carries out technical maintenance, replacement of attachments and partial repairs of gas turbine engines - GCU drives and MAPS. The electro-mechanical workshop of the Technical Maintenance Center that is equipped with modern equipment, implements overhauls of electric motors from 0.25 kW to 110 kW.

By executing the program of applying the modern methods of technical diagnostics of rotary equipment, C.E. Civil Engines Ltd established a “Diagnostic Center” in November 2017. The Diagnostic Center carries out technical diagnostics of rotary equipment with non-destructive monitoring methods, performs metrological testing of instrumentation and instrumentation systems, performs assembly and repair work on all types of technological equipment, organizes conferences with demonstration of novel innovations of diagnostic equipment for students and employees of the gas transportation industry. This project is implemented with the support of GE Oil & Gas, where their diagnostic equipment is purchased for the needs of the center.

Engine-Service LLC was established in May 2017. The founder of the enterprise is C.E. Civil Engines Ltd.

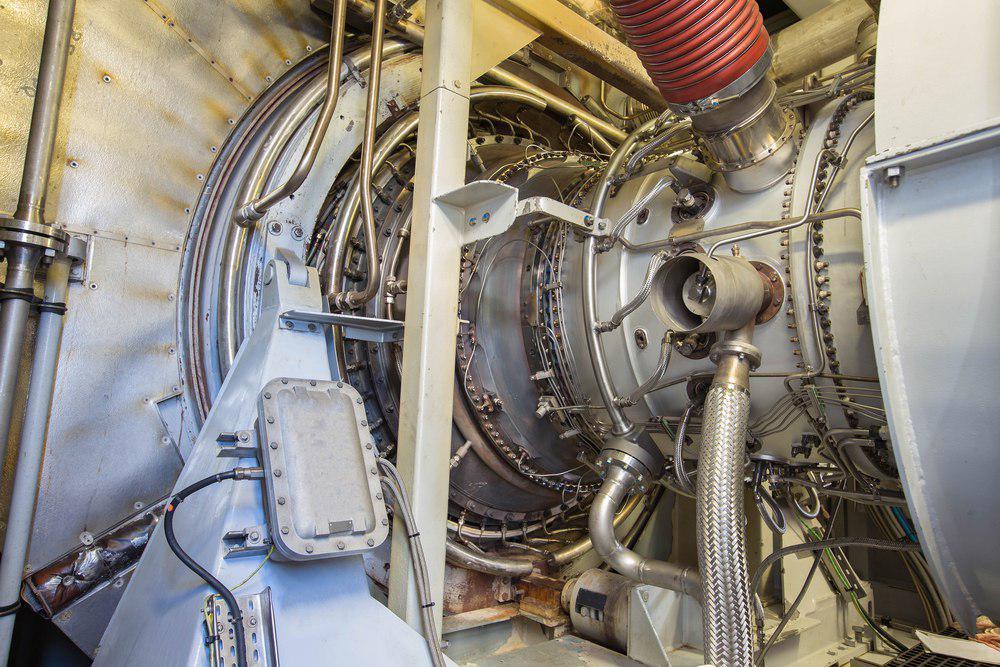

On the basis of the Engine-Service LLC, the Maintenance Center was established consisting of three workshops: the Maintenance and Repair Workshop for gas turbine engines (GTE); Workshop for repairing the electric motors from 0.25 kW to 110 kW; Workshop for repairing the filter cartridges GPR-138.00.010.

The staff of the Maintenance Center are all highly professional specialists with vast practical experiences that are capable of solving any given tasks quickly and efficiently. The Maintenance Center is equipped with modern instruments and specialized tools, which expand the capability of performing the tasks of any complexity.

Diagnostic Center was established in November 2017. The founder of the enterprise is the company C.E. Civil Engines Ltd. It implements technical diagnostics of rotary equipment with non-destructive monitoring methods, performs metrological testing of instrumentation and instrumentation systems, performs assembly and repair works on all types of process equipment and KIPandA system, carrying out of seminars with demonstration of novelties of the diagnostic equipment for students and specialists of the gas transportation industry.

The specialists of SDC are highly qualified and certified professionals with great practical experiences that are able to quickly and efficiently complete any tasks with the latest updated modern diagnostics and test instruments.

About company

About company